Temperature distribution in a valve suitable for operation with molten salts in a solar-thermal power plant

In the summer of 2011, the Institute for Hydraulic Fluidmachinery received an order for the numerical simulation of the temperature distribution in a control valve suitable for operation with molten salts.

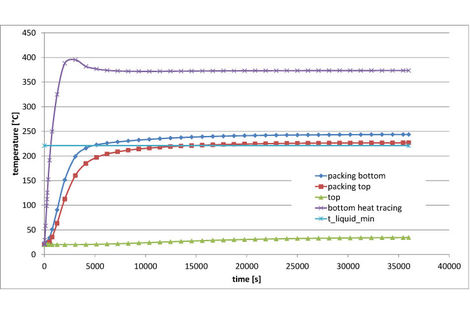

As in solar-thermal power plants very high temperatures of the heat transfer medium are required, apart from thermal oils e.g. molten salts are utilized as well. And, although molten salts provide nearly perfect characteristics for this field of application, one significant disadvantage ought not to be forgotten: crystallization of molten salts at low temperatures. In this case, the medium utilized crystallises below a temperature of 221°C. However, as the valves during plant operation have to be moved permanently for a controlled operation process, the necessary liquidus temperature of and at these components – especially the seals – may never fall below the above-mentioned limit. In order to make sure that this requirement is met, in most of the cases – apart from an excellent thermal isolation – an auxiliary heating device especially for the start-up process is inevitable.

During this project, for a control valve provided the thermal isolation together with the heating device should be modelled and optimised with special regard to a possible crystallizing.

For this purpose the geometry was imported into ANSYS 13, meshed and then modelled and calculated with the relevant boundary conditions. Apart from the observations in stationary mode, particular attention should be drawn to the starting and shut-down processes, for which the auxiliary heating to be installed was modelled.

By means of numerical simulation the ideal position as well as the necessary performance of the auxiliary heating device could be determined to inhibit future crystallizing of the heat transfer medium in the valve’s seals and thus enable smooth operation.

Kompetenzen

Standards & norms

- IEC 60193: Hydraulic turbines, storage pumps and pump-turbines – Model acceptance tests

- IEC 60534: Industrial-process control valves

- ISO 9906: Rotodynamic pumps – Hydraulic performance acceptance tests

- IEC 60041: Field acceptance tests to determine the hydraulic performance of hydraulic turbines, storage pumps and pump-turbines

- IEC 62006: Hydraulic machines – Acceptance tests of small hydroelectric installations

The list above is an excerpt. For the fulfillment of other standards please contact us.