Thermodynamic efficiency measurement

Thermodynamic efficiency measurements on hydropower plants provide data on the absolute efficiency of hydraulic machines such as turbines, pump turbines and pumps. By means of the so-called thermodynamic method plant efficiencies can be defined accurately within the range of kilowatt sizes up to multi-digit megawatt sizes. The measuring procedure is based on the flow losses in the water and measures the temperature increase in the mk range.

Fields of application

The determination of turbine efficiencies is an essential part during the analysis and optimisation process of existing hydropower plants. At the same time it provides the necessary data for an exact determination of a plant’s profitability (RoI - Return on Investment).

- Verification (review/authentication) of plant specifications guaranteed by a manufacturer by means of acceptance/approval measurements

- Identification of decreases in efficiency and of necessary maintenance, repair and

replacement works - Verifications before and after comprehensive revision and repair works

- Inventory of the current situation in order to set out optimisation potential

- Inspection and calibration of integrated measurement equipment

- Trouble shooting in the event of oscillations, pressure fluctuations and noise emissions

Measurements according to IEC standards

All our measurements are based on the internationally acknowledged IEC standards (International Electrotechnical Commission).

- Field acceptance tests to determine the hydraulic performance of hydraulic fluid machinery (turbines, pumps) are realised according to the standard IEC 60041 "Field acceptance tests to determine the hydraulic performance of hydraulic turbines, storage pumps and pump turbines".

- For measurements on small hydro power plants additionally IEC 62006 "Hydraulic machines – Acceptance tests of small hydroelectric installations", especially developed for such purposes, is applied.

Preparation and measurement campaign

The planning and the performing of the measurements are realised together with the client whereas the determination of the point of connection for the sensors is essential for the measurement accuracy. All necessary fixtures, installations and auxiliary devices can be designed and manufactured by our institute.

Analysis

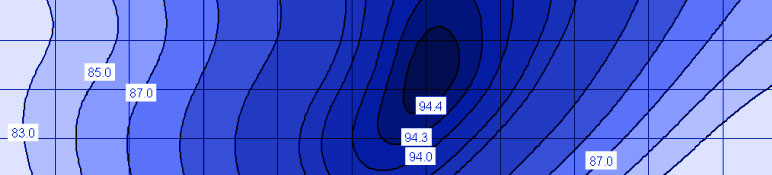

The first evaluation of the measurement results is already carried out on site. The final measurement report consists of measurement logs, graphical presentations of the measurement results, such as e.g. the hydraulic turbine efficiency in reference to the performance or the flow rate, or considerations on systematic and random errors at certain measuring points.

Advantages of thermodynamic efficiency measurements

- Determination of the absolute hydraulic efficiency up to an uncertainty of only 0,4 %

- Applicable to turbines, pump turbines and pumps

- Applicable to heads of > 100 m, upon agreement even to lower ones

- No flow / volume measurements required

Plant measurements worldwide.

Other methods offered and realised according to IEC standards:

| Flow rate:

| Transcient flow measurements:

|

Requests

Publications and additional information

Download

Brochure

Thermodynamic efficiency measurement

General information:

Institute of Hydraulic Fluid Machinery (HFM)