Location study for hybrid power plant "wind & water"

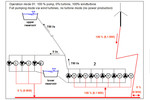

A feasibility study for a pumped storage power plant combined with a wind power station on an isolated island was realised for a private investor, an important general contractor and a turbine manufacturer. The power plant being subject of this pilot project should be designed for 5 MW wind power, 5 MW turbine power and 5 MW pump capacity, and it should provide network stability.

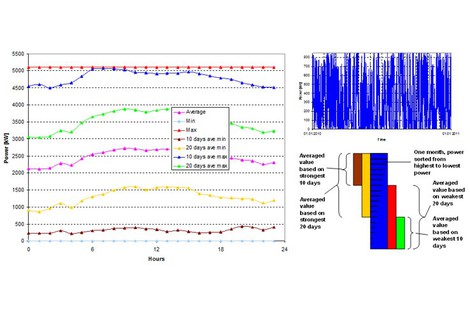

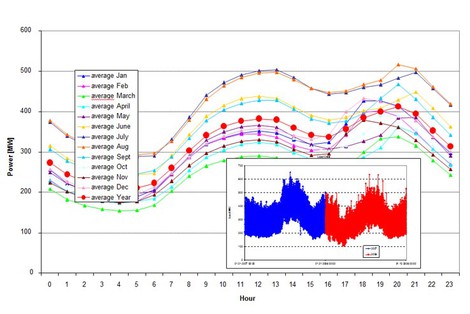

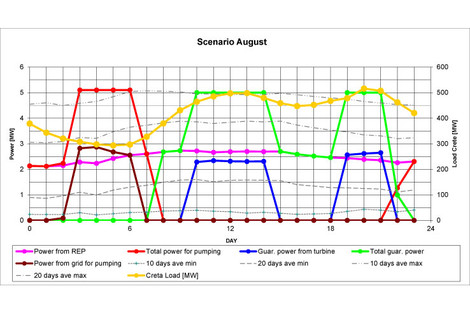

For the study, the wind conditions and grid parameters have been analysed for a period of two years and, based on reference data for an adjacent wind park, analyses have been established for each month. These analyses include the mean values as well as information on the best and the worst wind conditions during a certain month. The capacity development in the course of a day has been evaluated on a monthly basis and a monthly average value has been established, whereas it has to be stated that throughout the whole year the power production in the morning hours is generally lower.

However, the arithmetic average value provides no reasonable reference parameter as the turbines always produce a rather large quantity of power during the establishment of this mean value. Therefore, an exact segmentation is mandatory. So, the values for each month are split into best and weakest 10 and 20 daily averages. In July and August the network reaches maximum levels, followed by June and September, whereas the differences between daily minimum and daily maximum are significant (multiplication factor 2).

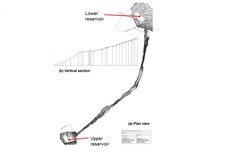

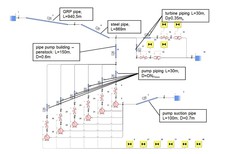

Based on the above-mentioned findings a comprehensive plant concept has been developed including turbine and pump analyses, installation plans, grid connection details and dimensioning of the headwater and the tailwater reservoir. And, based on this plant concept varying operation modes have been modelled, on the one hand to establish an economic evaluation and on the other hand to provide evidence that licence requirements can be met.

.

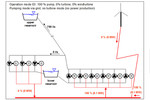

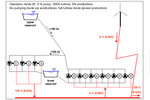

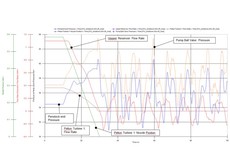

The hybrid power plant has to support several operation modes: 1. Pumped storage power generated from wind energy, 2. production of peak load energy, as well as 3. Pumped storage power generated from grid energy. For the time being, a hydraulic short circuit is excluded. Also, based on repeatedly tested models developed by our Institute, a comprehensive water hammer analysis has been carried out for the adequate dimensioning of the pressure pipeline and the necessary safety devices.

The parameters 8h/day with 5MW (40 MWh) on two consecutive days have been defined for a guaranteed production volume and safe operation. Based on the estimated efficiency levels a multiplication factor of almost 150% between turbine water volume and pump water volume is realistic, whereas the selection of an appropriate pipeline diameter provides for loss minimisation. Together with the calculated water evaporation, for 9.7 h in turbine mode subsequently 14.3h in pump mode are necessary.

.

For the purpose of water hammer calculations the total plant concept including headwater, pressure pipelines, turbines and pumps with the relevant piping as well as the tailwater have been modelled and simulated. The calculations proved that a system without surge tank or wind vessel is possible. The most critical load case would occur at simultaneous load rejection of all pumps. In order to avoid cavitation, additional oscillating weight is substantial.

Following these simulations, the plant concept has been adapted and modified in order to avoid convertion of the transmission line connection to the plant location; despite these adaption measures the designed plant is still profitable.