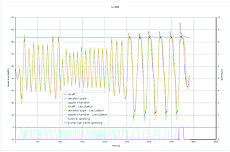

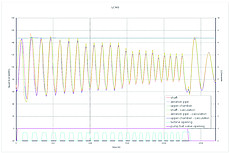

Transient calculation / water hammer

We calculate transient processes / water hammer calculation to develop, design and evaluate plants and machinery. There is the option for further research to combine the results of the transient calculations with experiments at our test rig.

Especially in the water supply and sanitation, as well as in energy technology, but also in process and automotive technology is the numerical simulation a very insightful analysis. For example, commissioning and shutdown of water supply investments are calculated exactly and which occur over and under pressures predicted as a function of time precisely. Maximum pressure peaks, flat dimensioning of relevant equipment and maximum pressure drops during deceleration of the fluid column, as this can result in excessive cavitation, which should be generally avoided.

Especially the modeling of cavitation-conditions that play a central rapidly increasing role in the development, design and control of injection systems for internal combustion engines, is - like the 3D - CFD - pursued at the moment with more interest.

Another focus of the development work is currently on the direct coupling of 1-dimensional and 3-dimensional design codes, thereby combining the advantages of both techniques can be used: on the one hand, the more accurate picture of individual components through the 3D simulation and on the other hand, the holistic, time-dependent treatment of complete , hydraulic systems through the 1D numerical simulation.

We do research, development, engineering, acceptance tests, field campaigns and consulting.