Hydraulic short circuit in a pump storage power plant

For a pump storage power plant which was originally designed for classical pumped storage operation (i.e. pumping resp. power consumption during the night and power production resp. turbining during the daytime) extensive analysis on the suitability for the operational mode of hydraulic short circuit were made. As the power plant was not built for it, the above mentioned operational mode would provide more flexibility during regular operation. Therefore, the effects of the distribution pipeline and the machine shaft in transient plant operation mode should be analysed in particular.

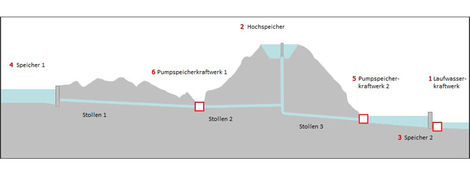

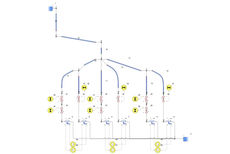

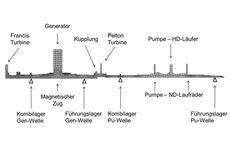

The power plant uses a high storage basin as headwater reservoir and the storage reservoir of a river power plant as downstream reservoir. The waterway of the plant consist of a vertical gallery and a tunnel made of concrete, approx. 1000m long, with distribution pipeline installed at its end. This pipeline feeds three machine sets, each one consisting of a Francis turbine and a double-flow two-stage storage pump. The complete distribution pipeline is cemented into the mountain, only about 3,5m just out into the air at the end of the six branches of the distribution pipeline are accessible from the outside. The Francis turbine, the storage pump, the motor generator and a small starting turbine represent one of three machine sets of this power plant.

During the analysis the effects of a hydraulic short circuit in the distribution pipeline, the transient plant behaviour and/or the water hammer phenomenon and the machine shaft have been investigated in detail.

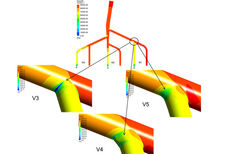

As the distribution pipeline is not accessible or only accessible during maintenance work which only take place in defined multi-annual cycles over, comprehensive CFD calculations were made in order to analyse the flow situation in the distribution pipeline and to compare the actual operational mode with the operation in hydraulic short circuit mode. It had to be investigated whether apart from the flow losses to be expected flow-induced pressure pulsations occur in the distribution pipeline, which interfere with the inflow into the turbines.

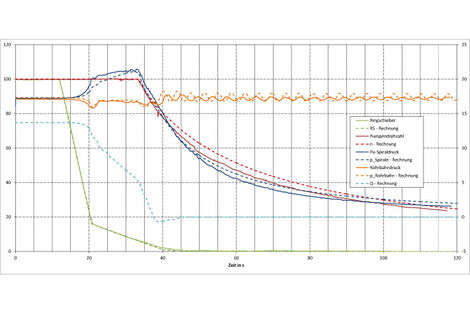

In order to examine the stationary and transcient hydraulic behaviour of the complete plant, more than 100 load cases were created and simulated during the water hammer calculations.

The analyses not only provided information on the occurring water hammers for the different operational modes, but also on plant flow rates in case of failures as well as in case of machine loads with excessive rotational speed or maximum torque. The data collected are occasionally required for the evaluation of the machine set load. Furthermore, to be able to realise the plant simulations with utmost exactness, the unknown hydraulic characteristics of the high storage reservoir’s intake construction as well as the shut-off valves of the hydraulic machines in the power house have been examined by means of CFD.

In the course of the structural analysis of the machine shaft the machine loads have been evaluated and the actual operational mode has been compared with the operation in hydraulic circuit mode. Moreover, a modal analysis of the machine set was carried out to detect possible vibration impulses.