Redesign of hydraulics for a Kaplan turbine

For a power plant site in the Middle East of a medium-sized company a redesign of the hydraulics for a Kaplan turbine has been realised.

The basic design of the blade was carried out one-dimensional on 6 partial flow turbine blades. The starting geometry was found by means of 3D calculations based on the Scholz-Czibere procedure, a computational singularity method tool developed at the Institute for Hydraulic Fluid Machinery which has often been applied successfully to the design of Kaplan turbines in the past years. The blade length or rather profile length has been defined by means of Thomann`s references for vertical Kaplan turbines which according to our observations repeatedly proved themselves as suitable parameters and can easily be optimised. The constants for the definition of the thickness and source functions are based on past experience gathered by the Institute for Hydraulic Fluid Machinery.

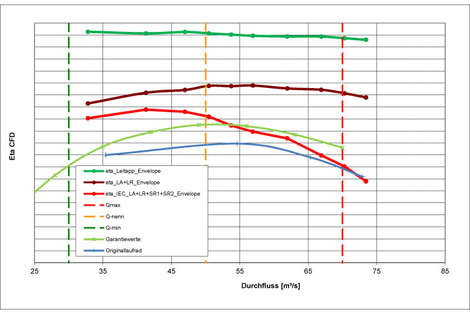

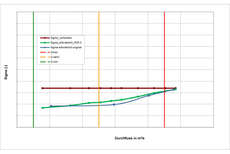

Kaplan turbine hydraulic: efficiency

For the Kaplan turbine hydraulics a maximum efficiency of 93% could be achieved. Furthermore, the total efficiency curve is flatter than for all blade variants presented before. It is also remarkable that up to Q=72.5m³/s the new curve is higher than the original curve. Within the flow region between Q=50m³/s and Q=60m³/s only another 4.25 % of efficiency get lost in the runner. Compared to all other blade variants tested, the improved runner outflow leads to a much more gentle increase in draft tube losses at overload.

Kaplan turbine hydraulic: cavitation sensitivity

For the purpose of an evaluation of the cavitation sensitivity of the redeveloped runner, the Sigma value (Sigma-pHisto0.005) necessary for a guaranteed cavitation-free operation of the runner was compared with the given Sigma parameter (available Sigma)

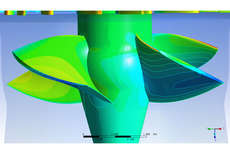

The small chart in figure 18 shows the pressure distribution (standardised) at the flow surfaces of the runner (pressure side and suction side). It is clearly visible that the pressure distribution in the area of the leading edge is homogenous on the pressure side as well as on the suction side.

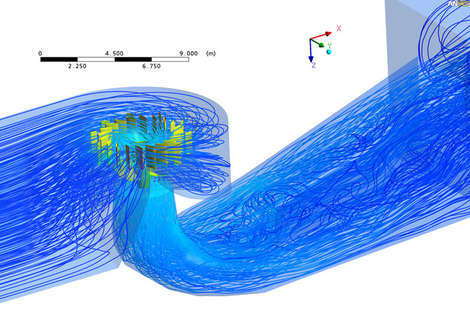

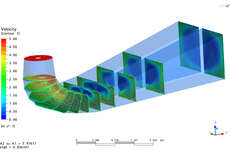

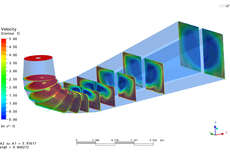

Kaplan turbine hydraulic: draft tube’s efficiency

As a final step of the optimisation procedure regarding the hydraulics for this Kaplan turbine, the draft tube’s efficiency as well as its capability to convert kinetic into static energy was evaluated and based on these findings the parameters for an ideal diffusor were defined. In case of an ideal draft tube flow situation the nominal flow rate allows for a diffusor efficiency value of hD=83.6% whereas the maximum flow rate allows for a diffusor efficiency value of hD=84%, which is quite near the maximum to be reached of 88%.

These detailed analysis presented show, that for this geometry the ideal diffusor has virtually been realised.

Core competences

Our services for turbines

- Product development

- Designing

- Optimisation

- Refurbishment

- Troubleshooting

» Details

We do research, development and optimisations for

- Hydraulics for turbines / pump turbines / pumps

- Acceptance tests acc. to IEC standards

- Nozzels

- Spirals

- Turbine in- and outtakes

- Valves & fittings

- Runners, guide vanes

- Water hammer

- Seals

- Surge chamber

- Penstock

- Refurbishment

- Efficiency

- Life cycle

- ...

We solve your challenge. Contact us.